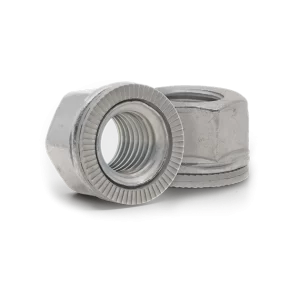

Nord-Lock Combi Nuts

Nord-Lock Combi Nuts

Nord-Lock created the original wedge-locking technology that secures bolted joints, even when exposed to severe vibration and dynamic loads. It is impossible for our products to loosen unintentionally due to the wedge created underneath the bolt head and nut.

- SKU: N/A

- Model: Combi Nuts

- Categories: Washers

- Material standard: EN 1.7182

- Product designation: NLCN

- Brand - Origin :Nord-Lock, UK

Description

Nord-Lock combi nuts are designed to simplify assembly, reduce installation errors, and improve operational efficiency by combining a standard nut with a pair of captivated Nord-Lock Original washers. This integrated design eliminates the risk of washer loss, streamlines serial production, and ensures secure bolted joints even in areas with limited accessibility.

Ideal for applications where space constraints and loose components complicate maintenance and assembly, combi nuts offer a vibration-resistant, anti-loosening solution. The washers feature cam faces on one side and serrations on the other, creating a powerful wedge-locking effect that prevents any rotational movement once the nut is tightened.

Movement occurs only across the cam surfaces, maintaining consistent clamping force and delivering long-term joint reliability. Perfect for manufacturers and industries that demand secure, maintenance-free bolted connections, Nord-Lock combi nuts are a smart, efficient choice for increasing productivity and reducing assembly time in challenging environments.

Benefits:

- Faster assembly

- Reduced risk of incorrect assembly

- Lower risk of parts coming loose

- Easier disassembly and reassembly during maintenance

- Less time required to maintain production

- Cost savings through improved productivity

Technical Specifications

| Applications | Machine building, Power Gen, Transportation, Railway | |||

| Washer material | EN 1.7182 | |||

| Hardening | Through hardened* | |||

| Washer hardness | >465 HV1 | |||

| Corrosion resistance | Minimum 600 hours in salt spray test (according to ISO 9227) | |||

| Temperature range | -50 to 150 C** | |||

| Bolt grades | 8.8 and 10.9 | |||

| Product designation | NLCN | |||

| Size range | M6-M16 | |||

| Plating | Zinc Nickel Plating (ZnNi) | |||

| Lubrication | Dry film lubricant | |||

| Property class | Class 10, ISO 898-2 | |||